- TAJIMA PULSE VECTOR TO STITCH SOFTWARE

- TAJIMA PULSE VECTOR TO STITCH CODE

- TAJIMA PULSE VECTOR TO STITCH SERIES

TAJIMA PULSE VECTOR TO STITCH SERIES

Series of move locations with control bits being triggered by 0x80 (-127).

TAJIMA PULSE VECTOR TO STITCH CODE

Triplet code has control bits on the final byte. The structure of the files is likely due to Pulse as well as Tajima's dominance in the industry in the 1990s.ģ.2.1 Command Encoding Schemes Code Length

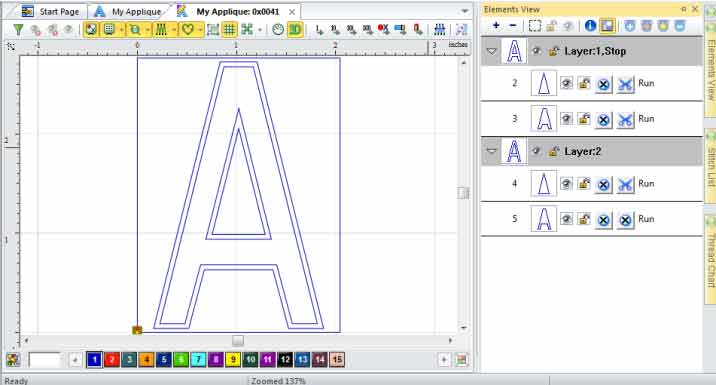

TAJIMA PULSE VECTOR TO STITCH SOFTWARE

dst files have a 512 block header starting with a label "LA: (NAME)" In 1982, Pulse Microsystems also developed the first PC software Stitchworks. For example Pulse developed the early software for Brother called PG1, it's also telling that the PEC blocks within Brother software just like in. The encoding of the format for the computer varies from company to company and software maker to software maker, but often share a common history. dst files is largely due to the age of the format but also because many formats are derived from them, and the early hardware was from the company that produced them. This means these formats are pretty easy to parse in binary and consequently access the stitch data therein. Embroidery machines do only a few things and those need to be easily encode in ways that the hardware can understand and execute. One consequence of the need to have simple machine readable formats is that when you cut away the headers, the formats can be used as interchange formats. Which is entirely what these files are intended as, executables. This is akin to having a different filetype for each executable for each different type of processor. These are specific ways that that particular hardware interacts. t? with other numbers that refer to other encodings.ĭifferent machines will have their own format specifically because the format consists of commands intended only for the particular machine in question. Literally these formats are identical and interchangeable, and you could create them by deleting the first 512 bytes from a dst file. To help matters, or rather make them worse, some companies like Wilcom will make new file types that just contain the stitch data. These different encoding schemes result in entirely new file types while not doing anything new. DSZ all have the same header information even though the stitch data is entirely different. But, it also means that some formats like. These are quite often specifically intended for exactly that display module. The header information is often of a specific length and contains a lot of display data for the machines. Given this requirement, the commands used within the machine code is often similar, sometimes identical when you get away from the header and into the actual stitches within the file. There are some cases like fringe where this is needed or puffy applique. It's possible with some machines to block the needle bar and move very far from the last stitch, others will force a trim. When enough of these are in a row, machines will often force a trim. The machines must stitch, unless the needle bar is blocked, which is the difference between a stitch and a jump. This encoding is also heavily influenced by the actual physical requirement of the machine. The stitch portions of files encode for three things: a control command, a dx, and dy. They are intended to control a stepper or servo motor, and a x-y plotter and a needle head. Often the actual controllers within the machines are similar and the encoding scheme for the embroidery files turns out to be quite similar. We will divide them up to avoid this confusion. While you could call them both "image files" it's a massive distinction.

It is like the difference between a complex layered photoshop file with undo history etc, and a jpeg. The most significant differences between embroidery files is the divide between intending to run a machine, and those intended to run the programs that create the files. We can however properly classify the problem. Any technical details in the article are for understanding why the formats are as they are.Ī lot of embroidery confusion is because there are diverse sets of hardware, and software and it is an unfathomable muddle. For technical details, see the specialized articles (menu to the right). This page attempts to provide a short overview on embroidery formats. Usually these try to preserve backwards compatibility because of the cost of the hardware in question. Some formats have different versions with increased features. There are several kinds of Embroidery file formats, and each contains different abilities and features.

0 kommentar(er)

0 kommentar(er)